Skutt KM714 Pottery Ceramic Kiln, 208/240 volt

- Regular Price

- $3,295.00

- Sale Price

- $3,295.00

- Regular Price

- Unit Price

- Translation missing: en.general.accessibility.unit_price_separator

Single piece design stainless steel jacket, equipped with single zone Kiln Master electronic control, 208/240 volt

Inside dimensions: 14½" wide x 13½" deep, fires to cone 8 / 2300°F, built with 2½" brick.

Comes with stand, peephole plugs, operating manual, instructional video, extra type K thermocouple, and warranty card.

Two Year Parts & Labour Warranty.

Skutt Kiln Warranty Statement

View the locating and electrical specification sheet.

Sophisticated, Yet Easy to Use

- Write your own firing programs with up to 32 Segments using Ramp and Hold. Now you can store up to 12 programs.

- … or use the tried and true factory set programs in ConeFire Mode

- Built in Diagnostics give you or our technicians the ability to diagnose kiln problems with just a few button presses.

- New Safety Features help prevent accidental starts and overfires.

- New software keeps track of your Firing Costs and the Number of Firings

- Fuse Glass, Slow cool Cone 6 Glazes, Grow Crystals…whatever you want to program this controller can handle.

- …and so much more. Click Here to see the whole story.

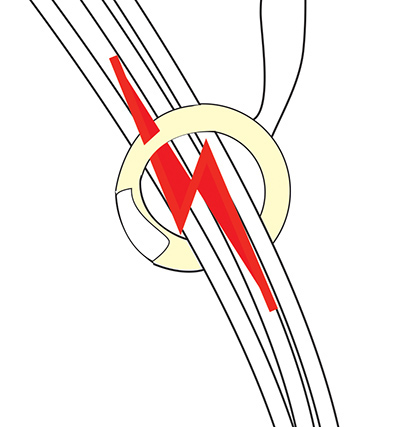

Current Sensing Technology

Skutt is one of the few brands that installs a Current Sensor in every KilnMaster Kiln. This allows you to read the Amperage of each section of the kiln as well as the Voltage and Voltage Under Load.

Now with the touch of a few buttons you can give those readings over the phone to your kiln repair technician so they can troubleshoot the problem and make sure they have the correct parts when they come out for the repair. This Saves Time and Money.

Prior to the use of these current sensors someone would have to come to your house and test the amperage and voltage inside the control box with live wires exposed. This system is Much Safer.

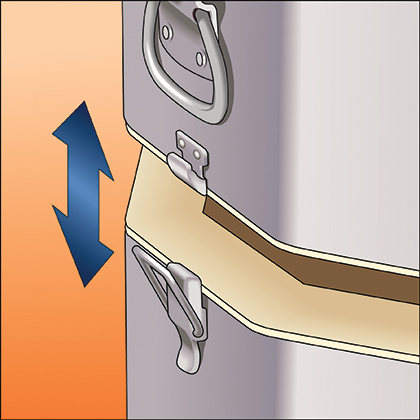

Sectional Design

Sectional Design is a good idea on so many levels.

Moving

Imagine trying to move a kiln into the basement or through a narrow door without being able to break it down into sections.

Repair

No more standing on your head in the kiln to replace those bottom elements or removing every brick in the kiln to get to the one you want to replace. Just remove the control box, unhook the buckles and place the section you want to work on on a table.

Replacement

We hope nothing really bad happens to your kiln … but … if it does, isn’t nice to know you can replace one bad section instead of the whole kiln?

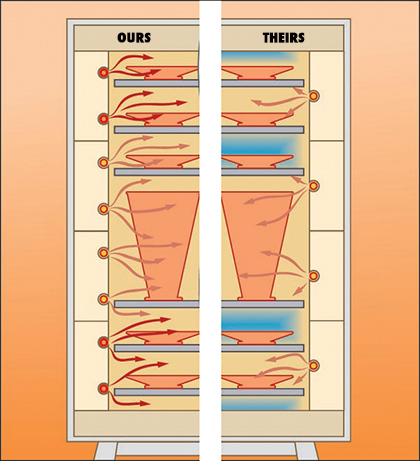

Balanced Elements

A large amount of the heat you lose in your kiln passes to through the lid and slab of your kiln. To compensate for this, Skutt directs more heat to these areas when they design the elements. The fact that we have twice the element grooves in our kilns gives us more design flexibility than some of our competitors.

It also gives you more loading options since it is always recommended to have at least one element radiating between each layer of shelves. Oh and by the way, twice the grooves means you get twice the amount of element wire, which means each element doesn’t have to work as hard, which means longer element life! Whew!

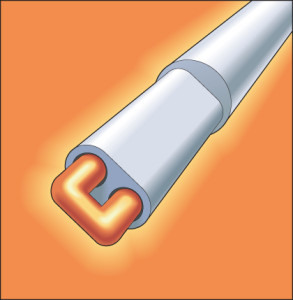

The Thermocouple

- Exposed Thermocouple equals faster reaction time and higher accuracy.

- Inexpensive, plus we give you an extra one when you buy your kiln.

- Easy and quick to replace.

- Type S (Platinum) Upgrades Available.

The Warranty

- Unlike most warranties, ours covers Parts AND Labor.

- Never Pro-Rated.

- Serviced by the most extensive, knowledgeable and talented distributor network in the industry.

- Backed by a company whose mission statement is “We help you make great things”. When your kiln is down, you can’t make great things.